Applications

FLAME RETARDANT

The use of lamellar additives produces a significant increase in the degradation temperature and a flame retardant effect due to the presence of char which is formed during the combustion of the nanocomposite.

This char is an inert and insulating coating that acts as a physical barrier between the polymer and the combustion zone. The physical barrier reduces oxygen ingress, slows down the combustion and reduces the emission of smoke and volatile substances.

P&T additives do not contain toxic substances and are halogen-free, in accordance with increasingly restrictive safety regulations, so they do not release dangerous substances during combustion.

Sectors of application:

Electronic (cable, electric and electronic devices)

Construction (flooring and structural panels)

Aerospace (panels and high-tech components)

Pipes, containers, bioplastics

Textile

MECHANICAL PROPERTIES

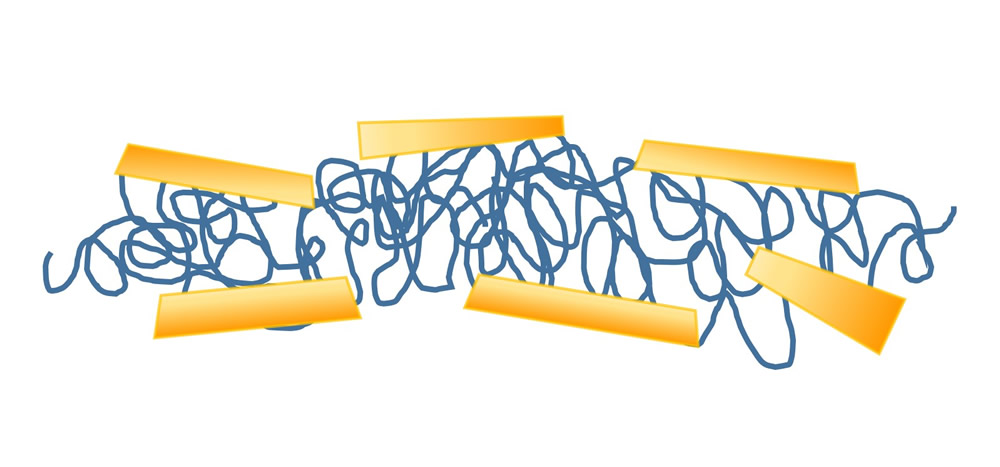

The interaction between the polymer chains and the lamellae therein dispersed produces a significant improvement in the mechanical properties.

The high aspect ratio (surface/thickness ratio) of the P&T additives confers to the nanocomposites greater hardness and better tensile, compressive and flexural strength. Moreover, additives are able to reduce the fracture in the molten state without significantly altering the viscosity and therefore the processability of the polymeric composites.

The high compatibility of the filler and the homogeneous dispersion at the nanometric level guarantee the good design and the absence of surface roughness in the composites obtaining lighter products with very high performances.

Sectors of application:

Automotive (tanks, bumpers, panels, tyres)

Construction (flooring and structural panels)

Aerospace (panels and high-tech components)

Pipes, containers, bioplastics

Film, packaging

BARRIER PROPERTIES

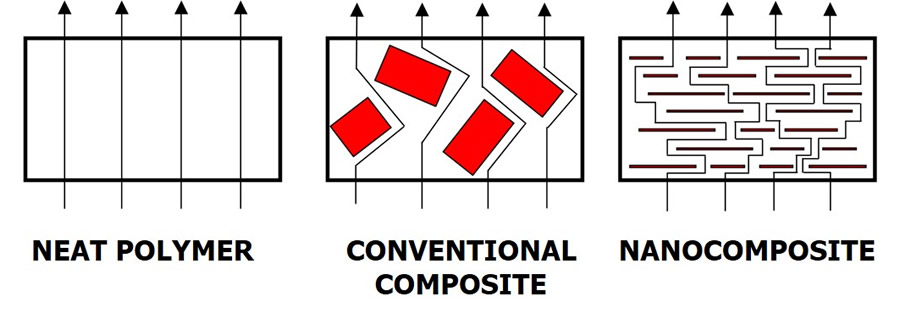

Filler lamellae constitute a physical barrier that opposes the transmission of gases and vapours (O2, CO2, H2O, solvents) through the nanocomposite. The high aspect ratio creates within the composite a tortuous path that traps the gas molecules and slows their diffusion (labyrinth effect).

The barrier is active both at the entrance, protecting the material by isolating it from unwanted gases and vapours, and at the outlet avoiding or slowing down the passage and the escape of volatile substances.

These properties are very important in the packaging sector, since the barrier guarantees the preservation of products (foods, beverages, drugs, cosmetics), maintaining unaltered their chemical/physical and organoleptic characteristics. Nanostructurant additives are able to significantly increase the shelf life of products avoiding the use of insulating coatings or multi-layered packaging.

Sectors of interest:

Packaging

Food packaging

Pharmaceutical/cosmetic packaging

Pipes, containers

-

NUCLEATING AGENTSOpen or Close

The exfoliation of the additives inside the polymeric matrix produces the uniform dispersion of lamellae or packets of few lamellae having a nanometric thickness.

These lamellae act as nucleating agent accelerating the crystallization of the polymer and improving both the productivity and the physical-mechanical properties of the composite material.

-

PLASTIFYERS DISPERSIONOpen or Close

The intercalation of plasticizing substances into the layered additives allows their dispersion in the polymer without evaporation, migration or solubilisation phenomena obtaining the desired plasticizing effect in terms of deformability, flexibility, elongation and mechanical resistance at low temperatures.

-

LUBRICANTSOpen or Close

The lamellar nature of the additives allows to improve the rheological and sliding properties of the molten polymer during processing.

These additives act as solid lubricants which facilitate the detachment of the polymer from the metal surfaces and speed up the production process.

-

UV PROTECTIONOpen or Close

The intercalation of UV absorbers in the lamellar solids allows the creation of additives capable of effectively filtering the UV radiation often responsible for film degradation or discoloration of the pigments.

Inclusion in the lamellar matrix produces a synergistic effect that increases the intensity of the absorbed radiation and widens the absorption band, further improving its effectiveness.

-

ANTISTATIC PROPERTIESOpen or Close

The modification of the hydrophobic/hydrophilic nature of the materials allows the preparation of additives of different polarity which, once migrated to the surface, dissipates static electric charges and reduces the accumulation of dust on the products.

-

ANTI-FOG PROPERTIESOpen or Close

The modification of the interlayer region of the additives by inserting molecules that prevent condensation of the water vapour and minimize the surface tension of the water allows to give the long-lasting anti-fog properties to the polymeric composite.

-

ANTI-CORROSIONOpen or Close

Hydrotalcites are able to mitigate and slow down corrosion thanks to the selectively capture chloride ions. Furthermore, the modification of the interlayer region of the additives by means of the intercalation of molecules which inhibit the corrosive phenomena confers to the polymeric composite the long lasting anti-corrosion properties.

-

ANTI-FOG PROPERTIESOpen or Close

The modification of the interlayer region of the additives by inserting molecules that prevent condensation of the water vapour and minimize the surface tension of the water allows to give the long-lasting anti-fog properties to the polymeric composite.

-

THERMAL AND ACOUSTIC INSULATIONOpen or Close

Lamellar additives after a suitable functionalization and dispersion in polymers for building construction can positively contribute to the thermal insulation, insulation and acoustic correction of the indoor noise.

-

ADDITIVE MANIFACTURINGOpen or Close

PT-Clay additives can be inserted in all the polymer matrices used for 3D printing with FDM (Fused Deposition Modeling) technology, in which the melted polymeric composite is deposited layer by layer to create the final geometry of the object.

-

ACTIVE FILLERSOpen or Close

The wide variety of intercalable organic modifiers in the interlayer region of the lamellar solids makes it possible to greatly expand the range of additive functionality and to create fillers with multiple properties.

Additives with antioxidant, antibacterial, antibiotic, biomedical, optical, magnetic or catalytic properties are just some examples.

HAVEN’T YOU FOUND THE APPLICATION OF YOUR INTEREST?