Nanotechnology to improve properties and performances of thermoplastic and thermosetting polymers and biopolymers.

The realization of polymeric nanocomposites allows the great improvement of the performances of polymers with small percentages of additive.

The PT-Clay additives are the result of the technological transfer of 30 years of academic research in the field of inorganic-organic lamellar solids. They offer effective solutions to modern technological and environmental challenges.

POLYMER ADDITIVES

A nanocomposite is a multiphase material made up of at least two components, one of which is dispersed in the other at nanometric level (10-9m).

Thanks to this dispersion, nanocomposites possess unique properties not shared by conventional polymeric composites or microcomposites, offering new technological and economic opportunities.

The nanostructuring additives for polymers can be classified according to their geometry and have one, two or three nanometric dimensions possessing respectively lamellar, tubular or spherical shape. Lamellar fillers are certainly the most interesting and used in the industry, because of their low cost and high versatility.

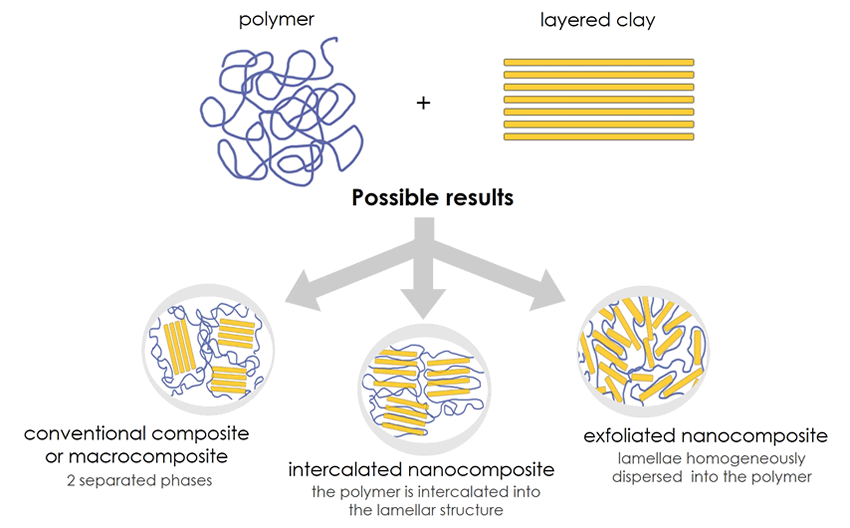

From a structural point of view, a composite material consisting of lamellar polymer/filler can be:

» A microcomposite, that is a composite in which two separate phases are observed, with a low interaction between the lamellae and the polymer chains;

» An intercalated nanocomposite, in which the polymer chains are partially intercalated in the interlamellar region and the filler maintains an ordered structure;

» An exfoliated nanocomposite, in which the lamellae are separated and homogeneously dispersed in the polymer matrix.

The exfoliated structure presents the maximum interaction between polymer and lamellae and it produces the maximum effect on the properties of the final nanocomposite.

The dispersion of a low amount of inorganic particles (up to 5% by weight in organic polymers) produces new composite materials with improved mechanical, gas and liquid barrier, flame retardant properties and chemical stability, if compared to the neat polymer.

The introduction of special metals in the additive structure can also induce optical, catalytic, electrical or magnetic properties in the polymers. When the additive is exfoliated into the polymer, the final nanocomposite retains its original colour or transparency, as the filler particle size is less than the wavelength of visible light.